Business Objective

Analyse sales and operations processes, including back office, with a view to seeking standardisation, automation and improve efficiency where appropriate. This analysis must be connected to optimise internal use of business systems.

Current Situation and Background

Sales, Operational & Quality Processes

Sales – 17% of Sales Time is spent on quotations and is non value add, there is duplication of effort, 3 different systems, including Word to generate sales quotes. Efficiency within the process must be increased and not just add more admin.

Operations – There is a requirement for a transparent e2e operational management system. Many of operational activities undertaken by Sales, circ 18% Sales person time is chasing product through the manufacturing process or progress and internal status. Planning of production, capacity , supplier management, installation and operations is not integrated and is inefficient, no clear ownership.

Quality – No evidence of closed loop corrective action or analysis of available data. There is an upward trend in warranty claims on some product lines, albeit reducing recently.

Analysis and Recommendations

Diagnostics, data gathering and analyse were undertaken across the three areas of improvement, with Process Mapping, SIPOC (suppliers, inputs, process, outputs, customer), Organisational Structures and project plans completed for implementation

Business Improvement Priorities

Project Management and Implementation with Practitioners and Internal Customer Team.

Priority Improvements:

- Design and Implement sales quotation process, enhancing the existing quotation systems and creating a single integrated quotation tool.

- Design and Implement end to end Operational management system and structure to take responsibility for all Equipment operational tasks from order receipt to invoice of completed units

- Design and Implement end to end Customer Quality System, focussing on Product quality, internal and external process adherence, in all functions and at all levels. Where appropriate adopt 8D problem solving process.

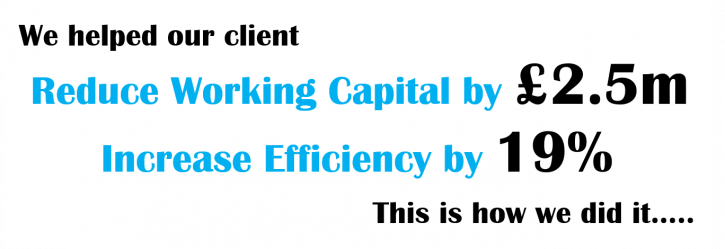

Business Achievements

- Working Capital Savings £2.5m

- Operational Efficiency Increased by 19%

- Cost of Poor Quality Saving £256k

- Operations Restructure to ensure Customer Satisfaction and Delivery

- On Time Delivery Improved by 27%

Product Shortages Eliminated - 35% of Sales Engineers Time released for Value Added Customer Activities

- Enquiry to Proposal Reduced by 72%