Activity sampling, coupled with time study techniques, has, unfortunately, become a forgotten art within the realm of present-day manufacturing. As was once meticulously drilled into eager minds, everything eventually comes down to time. It is thus essential to scrutinize the best and most efficient utilisation of time for all our undertakings.

While there are myriad tools available, activity sampling stands out as one of those formidable tools to always have in your armory. It’s a phenomenal method that enables economically studying extended activities or a group of such activities, yielding statistically accurate data.

Understanding Activity Sampling?

To delve deeper into the concept of activity sampling, imagine a group of machines, processes, or people observed over an extended period. At regular intervals, the observer records the ongoing activities at random periods of the day/week. Every observation precisely notes what is happening at a given time—eventually building a measure of the percentage of time the activity spans over the hour, day, or any chosen timeline.

This method proves especially useful in estimating the proportion of value-added time to non-value added time within your business processes. Typical observations may cover instances such as machine breakdowns, transportation of material, change-overs, periods of waiting, operating, and paperwork filling, etc. Although these examples tilt more towards manufacturing operations, the method is equally vital in examining back-office processes and identifying potential time-consuming activities to boost personal productivity.

An Example Activity Sampling in Action

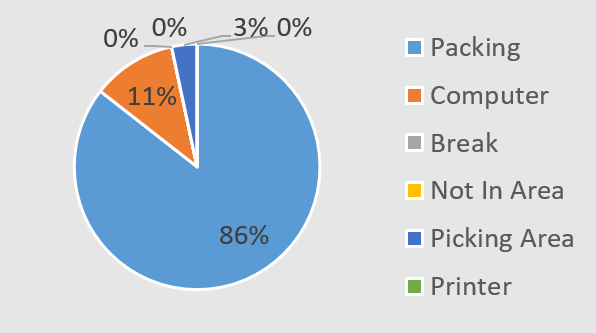

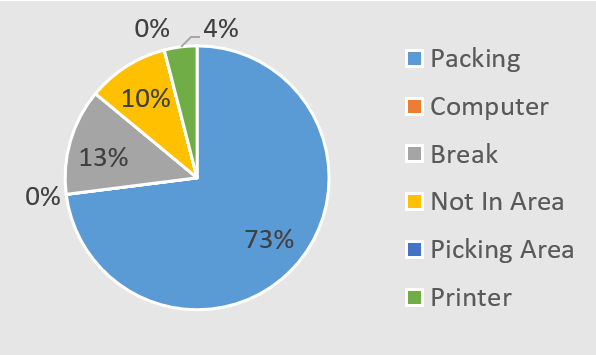

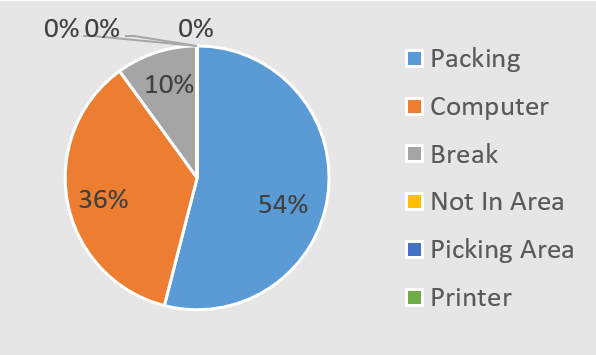

Let’s take a practical example to understand these observations. Consider sampling the activity of ‘packing’ involving three people/processes. The activity is conducted over two hours at random times of the day/week, with observations taken every two minutes. The results can be illustrated visually to represent allocated percentages for each task.

This analysis provides an opportunity to identify possible improvements to work smarter (and not necessarily harder). The process can be augmented by a spaghetti diagram to emphasise material and person movements, detailed time study work, and process mapping.

When analysing, one may notice that Packing Process 2 showcases no computer time within the two hours. Upon further inquiry and understanding, one realizes that Packing Process 2 batches their paperwork before processing it in one hit. Activity sampling would help identify this difference wherein the observation percentage compared to the other two processes would have been higher.

The Benefits of Activity Sampling

Activity sampling presents numerous advantages. It offers unbiased results and can be paused at any point without compromising the results. It’s a technique that can be mastered even with limited training. It allows teamwork to be studied and compared. Given its economical nature, it’s also less time-consuming than many other traditional time-study techniques.

A Final Word

Today’s competitive and fast-paced world demands sharp insights and efficiency across the board. The lost art of activity sampling, if recovered and embraced, can play a critical part in maintaining competitiveness and driving consistent improvements in productivity for businesses in any industry.

So, the question beckons. Are we ready to rediscover this lost art to maximise our potential and fulfil our quest for increased productivity and efficiency?