Now most of us know and understand Standard Work, and hopefully when I say standard work your thinking of Process Capacity Tables (PCT), Standard Work Combination Tables (SWC), Standard Work Layout (SWL) and Standard Operating Procedures (SOP) and NOT just standard operating procedures????.

As a refresher

- PCT – illustrates the production capacity of each process involved in producing a part.

- SWC – combines human movement and machines cycle times based on Takt time.

- SWL – A cell which is able to meet changing Customer requirements, as identified by Takt Time, with any number of Team Members, whilst maintaining productivity, without the waste of waiting.

- SOP – is the document that details the current best method of operation. It includes quality checks, safety checks and any other activities that are included in the standard operation.

Now standard work also applies to management! Known as Leadership Standard Work.

Not to be confused:

Standard Work = a tool used to provide consistency of outcome

Leadership Standard Work = provides a structure and routine

It follows these three keys to leadership

- Go See – spend time on the frontlines, be it, manufacturing, service, health sector, finance, etc.

- Ask Why – use the “Why technique daily”

- Show Respect – Respect your people

Leadership standard work is about walking the frontlines, seeing the abnormal from normal conditions. What is the work that’s is being done? What is the process? Is it adhered to? Are the business results being achieved? What is the next improvement that has been identified?

Leadership Standard Work in the case of a Production Manager may involve

- A daily plan

- A workplace walk across all areas

- A conversation with a person from each area

- Checking that Senior Management walks are completed

- Is the 5S to the agreed standard?

- Are actions being closed out?

- Etc.

As we go up the hierarchy the standard work may become weekly, monthly, quarterly, etc.

A Senior Manager or General Manager may do the following:

- Weekly frontline walk to touch base with associates, supervisors in each area to understand how the plant is running.

- Spend time in the problem solving meetings, asking why, coaching and mentoring

- Checking all critical audits are complete?

- Are standards being adhered to?

- Etc.

Frontline associates see things first and we want to let them know what to do and feel at ease in highlighting the abnormal from normal conditions.

Leadership Standard Work is based on walking the frontline, observing waste and abnormalities, asking questions and supporting the improvement process.

By embedding this practice, leaders can begin to create a culture that:

- Solves problems quickly and permanently.

- Drives continuous improvement.

- Develops the next generation of leaders.

- Make continual gains in performance.

- Embeds the culture of team working.

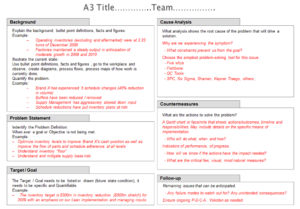

My early appreciation and benefit of this practice was implementing it at Unipart early 2000’s. It was implemented throughout the structure, from Team Leader to Managing Director, an example of which is the image above, showing the leadership pyramid/timing and Senior Manager standard work. Due Diligence is key to this practice, not paying it lip service or tick in the box mentality.